Alamar biodobagable alluna

Hanyoyi da dama masana'antu masu yawa suna da amfani (watau babban nauyin kwayar halitta) Pla. Ana amfani da manyan abubuwan da aka yi amfani da su guda biyu: lactic acid, da cyclic di, lactide. Hanyar da aka fi amfani da ita zuwa Pluri ita ce ta buɗe polymerization na Lactide tare da abubuwa daban-daban (yawanci tin octoate) a cikin bayani ko azaman dakatarwa. Hakikanin motsa jiki na karfe yana haifar da tseren jirgi na PLIN, yana rage karfinsa idan aka kwatanta da kayan farawa (yawanci masara).

Pluri mai narkewa ne a cikin kewayon karuwa na kwayoyin halitta. Ethyl Acetate, saboda kwanciyar hankali da ƙarancin haɗarin amfani, shine mafi yawan sha'awa. Pla 3D Fayilolin Fayil na 3D Distolves lokacin da aka soaked a cikin ethyl acetate, ya sa shi amfani mai amfani ga tsaftace kai na 3d buga ko cirewa goyon baya. The tafasasshen yanayin ethyl acetate ya ragu sosai ga santsi a cikin ɗakin tururi, mai kama da amfani da acetone tururi don dacewa da AC.

Sauran amintattun hanyoyin amfani don amfani sun haɗa da carbonatepylene carbonate propylene, wanda yake mafi aminci fiye da ethyl Acetate amma yana da wuya a sayi kasuwanci. Hakanan za'a iya amfani da Pyridine duk da haka ba shi da lafiya fiye da ethyl acetate da carpylene carbonate. Hakanan yana da banbancin kifi mara kyau.

SPLA magance fasali

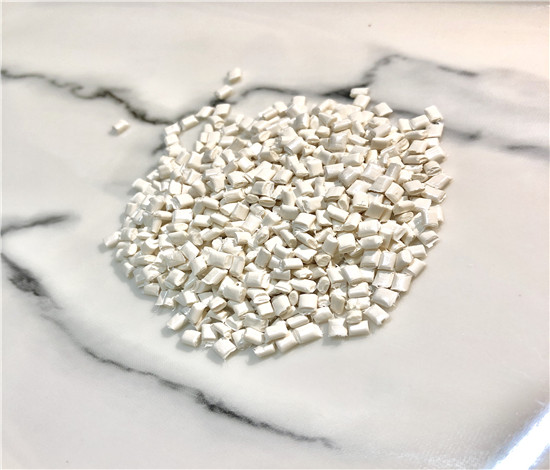

Babban kayan aikin samfur na samar da kayan aiki, pbat da inorganic irin wannan nau'in samfurin yana da kyakkyawan narkewar narkewar kayan aikin injin, kuma yana da dacewa da allurar rigakafi. Zai iya samar da samfuran da yawa-dorewa da lokaci mai sanyaya, lowripti, da lalata sauri. Samfurin yana da kyakkyawan aiki da kuma ilimin jiki, kuma ana iya amfani dashi kai tsaye don yin gyara don yin samfuran samfuran da aka yi amfani da su.

SPLA magance aikin aikace-aikacen

Babban ƙarfi, ƙarfi mai ƙarfi na 3D buga kayan da aka gyara,

Farashi mai ƙarfi, ƙarfi na 3Da 3D

SPLA allurar rigakafi mai gyara da bayanin

| Sa | Siffantarwa | Umarnin sarrafawa |

| SPLA-Im115 | Babban kayan aikin samfur na samar da kayan aiki, pbat da inorganic irin wannan nau'in samfurin yana da kyakkyawan narkewar narkewar kayan aikin injin, kuma yana da dacewa da allurar rigakafi. | Lokacin amfani da wannan samfurin don allurar gyada, ana bada shawara cewa zazzabi aiki ya zama 180-195 |