Cikakken polymers - polymers waɗanda ke daidaita kaddarorin jiki da tasirin muhalli - babu su, amma polybutylene terephthalate (PBAT) ya fi kusa da kamala fiye da da yawa.

Bayan shekaru da yawa na kasa dakatar da samfuran su suna ƙarewa a cikin matsugunan ruwa da kuma tekuna, masu yin polymer roba suna fuskantar matsin lamba don ɗaukar nauyi. Mutane da yawa suna ninka ƙoƙarinsu na haɓaka sake yin amfani da su don kawar da zargi. Wasu kamfanoni suna ƙoƙarin magance matsalar sharar gida ta hanyar saka hannun jari a cikin robobin da ba za a iya cire su ba kamar su polylactic acid (PLA) da polyhydroxy fatty acid esters (PHA), da fatan gurɓacewar yanayi zai rage aƙalla wasu sharar.

Amma duka sake yin amfani da su da kuma biopolymers suna fuskantar cikas. Misali, duk da kokarin da aka yi na tsawon shekaru, Amurka har yanzu tana sake sarrafa kasa da kashi 10 na robobi. Kuma polymers na tushen halittu - galibi samfuran fermentation - suna gwagwarmaya don cimma aiki da sikelin polymers ɗin roba waɗanda ake nufi don maye gurbinsu.

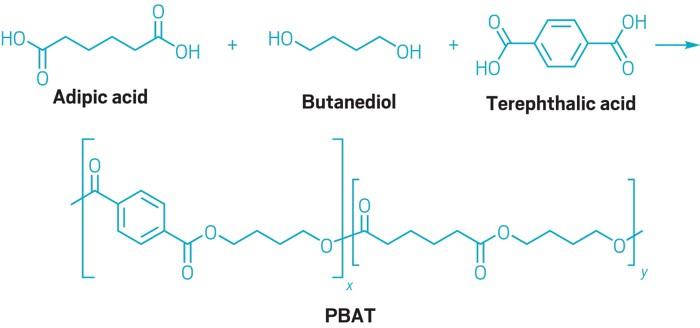

PBAT ya haɗu da wasu kaddarorin masu amfani na polymers na roba da na tushen halittu. An samo shi daga samfuran petrochemical na kowa - mai ladabi terephthalic acid (PTA), butanediol da adipic acid, amma yana da biodegradable. A matsayin polymer roba, ana iya samar da shi cikin sauƙi, kuma yana da abubuwan da ake buƙata don yin fina-finai masu sassauƙa da kwatankwacin na robobi na gargajiya.

Sha'awar PBAT yana karuwa. Kafaffen kera irin su BASF na Jamus da Novamont na Italiya suna ganin karuwar buƙatu bayan shekaru da yawa na ciyar da kasuwa. Masu kera Asiya sama da rabin dozin sun haɗu da su waɗanda ke tsammanin kasuwanci don haɓakar polymer ya bunƙasa yayin da gwamnatocin yanki ke matsawa don dorewa.

Marc Verbruggen, tsohon Shugaba na PLA manufacturer NatureWorks kuma yanzu mai ba da shawara mai zaman kansa, ya yi imanin cewa PBAT shine "samfurin mafi arha kuma mafi sauƙi don ƙera" kuma ya yi imanin cewa PBAT ya zama mafi mahimmancin bioplastic, Yana gaba da poly succinate butanediol ester. PBS) da PHA masu fafatawa. Kuma yana iya zama matsayi tare da PLA a matsayin manyan robobi biyu mafi mahimmancin ƙwayoyin cuta, wanda ya ce yana zama babban samfuri don aikace-aikace masu tsauri.

Ramani Narayan, farfesa a fannin injiniyan sinadarai a Jami'ar Jihar Michigan, ya ce babban wurin siyar da PBAT - ta biodegradability - ya fito ne daga ester bonds, maimakon carbon-carbon kwarangwal a cikin wadanda ba rushe polymers kamar polyethylene. Ester bonds ana samun sauƙin hydrolyzed da lalacewa ta hanyar enzymes.

Misali, polylactic acid da PHA sune polyester da ke lalata lokacin da haɗin ester ɗin su ya karye. Amma mafi yawan polyester - polyethylene terephthalate (PET), da ake amfani da su a cikin zaruruwa da kwalabe na soda - baya rushewa da sauƙi. Wannan saboda zoben ƙamshi a cikin kwarangwal ɗinsa ya fito ne daga PTA. A cewar Narayan, zoben da ke ba da kaddarorin tsarin su ma suna yin PET hydrophobic. "Ruwa ba shi da sauƙi don shiga kuma yana ragewa dukkanin tsarin hydrolysis," in ji shi.

Basf yana yin polybutylene terephthalate (PBT), polyester da aka yi daga butanediol. Masu bincike na kamfanin sun nemi polymer mai iya lalacewa wanda za su iya samarwa cikin sauƙi. Sun maye gurbin wasu PTA a cikin PBT tare da adipose diacid glycolic acid. Ta wannan hanyar, an raba sassan ƙamshi na polymer don su iya zama biodegradable. A lokaci guda kuma, an bar isasshen PTA don ba da kayan aikin polymer mai mahimmanci.

Narayan ya yi imanin cewa PBAT yana da ɗan ƙara haɓakar halittu fiye da PLA, wanda ke buƙatar takin masana'antu don bazuwa. Amma ba zai iya yin gogayya da PHAs na kasuwanci ba, waɗanda ke da lalacewa a cikin yanayin yanayi, har ma a cikin mahallin ruwa.

Masana sukan kwatanta kayan PBAT na zahiri da ƙananan polyethylene, polymer na roba da ake amfani da su don yin fina-finai, kamar jakunkuna na shara.

PBAT sau da yawa ana haɗe shi da PLA, polymer mai ƙarfi tare da kaddarorin polystyrene. Alamar Basf's Ecovio ta dogara ne akan wannan gauraya. Misali, Verbruggen ya ce jakar siyayyar takin zamani ta ƙunshi 85% PBAT da 15% PLA.

Novamont yana ƙara wani girma ga girke-girke. Kamfanin ya haɗu da PBAT da sauran polyesters aliphatic aromatic polyesters tare da sitaci don ƙirƙirar resins don takamaiman aikace-aikace.

Stefano Facco, sabon manajan ci gaban kasuwanci na kamfanin, ya ce: “A cikin shekaru 30 da suka gabata, Novamont ya mai da hankali kan aikace-aikace inda iyawar lalacewa na iya ƙara ƙima ga samfurin kanta. "

Babban kasuwa na PBAT shine ciyawa, wanda aka yada a kusa da amfanin gona don hana ciyawa da kuma taimakawa wajen riƙe danshi. Lokacin da aka yi amfani da fim din polyethylene, dole ne a cire shi kuma sau da yawa a binne shi a cikin wuraren da aka kwashe. Amma ana iya noma fina-finan da za a iya lalata su kai tsaye zuwa cikin ƙasa.

Wata babbar kasuwa ita ce buhunan shara na takin don hidimar abinci da tattara kayan abinci da sharar gida.

An sayar da jakunkuna daga kamfanoni irin su BioBag, wanda Novamont ya samu kwanan nan, a dillalai na tsawon shekaru.

Lokacin aikawa: 26-11-21