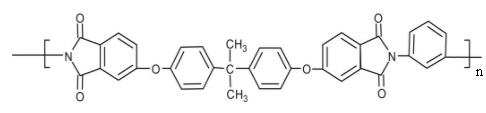

Polyetherimide, wanda ake magana da shi a matsayin PEI a cikin Ingilishi, Polyetherimide, tare da bayyanar amber, wani nau'in filastik ne na injiniya na musamman na amorphous wanda ke gabatar da haɗin ether mai sassauƙa (- Rmae Omi R -) cikin ƙwayoyin sarkar polyimide mai tsayi.

Tsarin PEI

A matsayin nau'in polyimide na thermoplastic, PEI na iya haɓaka ƙarancin ƙarancin thermoplasticity da wahala aiki na polyimide ta hanyar gabatar da haɗin ether (- Rmurmurr R -) a cikin babban sarkar polymer yayin da yake riƙe da tsarin zobe na polyimide.

Halayen PEI

Amfani:

Ƙarfin ƙarfi mai ƙarfi, sama da 110MPa.

Babban lankwasawa, sama da 150MPa.

Kyakkyawan ƙarfin ɗaukar hoto na injiniyoyi, zafin nakasar zafi sama da ko daidai da 200 ℃.

Kyakkyawan juriya mai rarrafe da juriya ga gajiya.

Kyakkyawan jinkirin harshen wuta da ƙananan hayaki.

Kyakkyawan dielectric da insulation Properties.

Kyakkyawan kwanciyar hankali mai girma, ƙarancin haɓakar haɓakar thermal.

High zafi juriya, za a iya amfani da a 170 ℃ na dogon lokaci.

Yana iya wucewa ta cikin microwaves.

Rashin hasara:

Ya ƙunshi BPA (bisphenol A), wanda ke iyakance aikace-aikacen sa a cikin samfuran da suka shafi jarirai.

Matsayin tasiri mai hankali.

Juriya na Alkali ya zama gama gari, musamman a yanayin dumama.

KYAUTA

Sunan kimiyya PEEK polyether ether ketone wani nau'in polymer ne wanda ya ƙunshi haɗin ketone ɗaya da ether bond biyu a cikin babban tsarin sarkar. Abu ne na musamman na polymer. PEEK yana da kamannin m, kyakkyawan tsari, zamewa da juriya, juriya mai kyau, juriya mai kyau sosai, juriya mai kyau ga hydrolysis da tururi mai zafi, babban zafin jiki mai zafi, babban zafin nakasar thermal da kyakkyawan jinkirin harshen wuta.

An fara amfani da PEEK a fagen sararin samaniya don maye gurbin aluminum, titanium da sauran kayan ƙarfe don kera sassan ciki da waje na jirgin. Saboda PEEK yana da ingantattun kaddarori masu kyau, yana iya maye gurbin kayan gargajiya kamar ƙarfe da yumbu a fagage na musamman da yawa. Yawan juriya da zafinsa, mai mai da kansa, juriya da juriya da gajiya sun sanya ta zama ɗaya daga cikin fitattun robobin injiniyoyi masu inganci.

A matsayin kayan aikin polymer na thermoplastic, halayen PEI sun yi kama da na PEEK, ko ma maye gurbin PEEK. Bari mu dubi bambanci tsakanin su biyun.

| PEI | KYAUTA | |

| Yawan yawa (g/cm3) | 1.28 | 1.31 |

| Ƙarfin Tensile (MPa) | 127 | 116 |

| Ƙarfin Flexural (Mpa) | 164 | 175 |

| Hardness Indentation Ball (MPa) | 225 | 253 |

| GTT(Glass-Tsarin Zazzabi) (℃) | 216 | 150 |

| HDT (℃) | 220 | 340 |

| Zazzabi na Aiki na dogon lokaci (℃) | 170 | 260 |

| Takamaiman Juriya (Ω) | 10 14 | 10 15 |

| UL94 Flame Retardant | V0 | V0 |

| Shakar Ruwa (%) | 0.1 | 0.03 |

Idan aka kwatanta da PEEK, cikakken aikin PEI ya fi daukar ido, kuma babbar fa'idarsa ta dogara ne akan farashi, wanda kuma shine babban dalilin da yasa wasu kayan ƙirar jirgin sama suka zaɓi kayan haɗin gwiwar PEI. Cikakken farashi na sassan sa ya yi ƙasa da na ƙarfe, na'urorin sarrafa thermosetting da PEEK composites. Ya kamata a lura cewa ko da yake aikin farashi na PEI yana da girma, juriya na zafin jiki ba shi da yawa.

A cikin chlorinated kaushi, danniya fatattaka yana faruwa a sauƙi, kuma juriya ga kwayoyin kaushi ba shi da kyau kamar na Semi-crystalline polymer PEEK. A cikin sarrafawa, ko da PEI yana da ikon sarrafa robobi na injiniyoyi na thermoplastic na gargajiya, yana buƙatar zafin narke mafi girma.

Lokacin aikawa: 03-03-23