A samar da tsari na modified roba barbashi yafi hada da: hadawa tsari, extrusion tsari, marufi.

1. Gwaje-gwaje shida na haɗuwa: lissafin kuɗi, karɓa, tsaftacewa, rarrabawa, lilo, haɗuwa.

2. Tsabtace na'ura: an raba shi zuwa maki hudu A, B, C da D, wanda An shine mafi girma (smooth surface), da sauransu.

3. Rarraba kayan aiki: tabbatar da cewa ba za a yi kuskuren abubuwan da suka dace ba a cikin aikin.

4. Hadawa: tsari na gama gari shine: foda foda, toner.

Ⅱ.Ciyarwa.

Ta hanyar sarrafa kwamfuta, ana sarrafa blanking bisa ga canjin nauyi.

Amfani:

1. Tabbatar da daidaiton rabon kayan aiki.

2. Rage delamination na kayan.

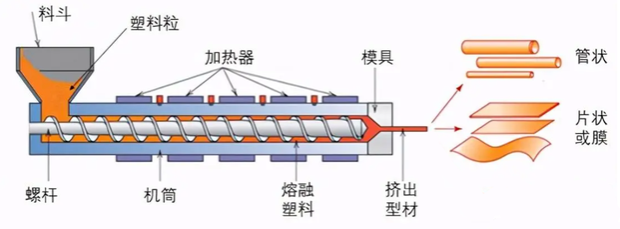

Ⅲ.Dunƙule plasticizing, extrusion, zane.

Ⅲ.Dunƙule plasticizing, extrusion, zane.

Ⅳ.Ruwan sanyaya (ruwan ruwa).

Cool da kwantar da tuber filastik da aka fitar daga extruder.

Ⅴ.Bushewar iska (famfon ruwa, wukar iska).

Cire danshi daga tsiri na filastik kuma bushe shi.

Ⅵ.Granulation.

Kullum, girman da yanke barbashi ne 3mm * 3mm PVC abu misali: GB / T8815-2002.

Ⅶ.Sifting (allon jijjiga).

Tace ɓangarorin da aka yanke kuma sarrafa girman abubuwan.

Ⅷ.Overmagnetization (magnetic tace).

A tsotse barbashi tare da ƙazantattun ƙarfe.

Ⅸ.Binciken kan-site.

Shi ne galibi kula da bayyanar, wanda ke gano ko launin barbashi ya kai daidai da ko an haɗa shi.

Ⅹ.Hadawa (mai jujjuya mazugi biyu).

Tabbatar cewa launi da aikin ɓangarorin filastik da aka gyara sun kasance iri ɗaya.

Ⅺ.Marufi (dukkan-lantarki marufi marufi).

Ⅻ.Adanawa

Lokacin aikawa: 23-12-22